Chemical Inventory System

Our Inventory Management Software is powerful enough to help you manage the complex variables pertaining to industrial barrels and drums. You can also track them as they are moved to and from internal storage locations and customer sites. Our industry-leading Inventory System‘s comprehensive set of features helps to simplify the processes involved in managing chemical inventory while meeting compliance criteria. Our inventory management software aids with inspection, cleaning, and refilling, ensuring smooth operations and adherence to regulatory standards.

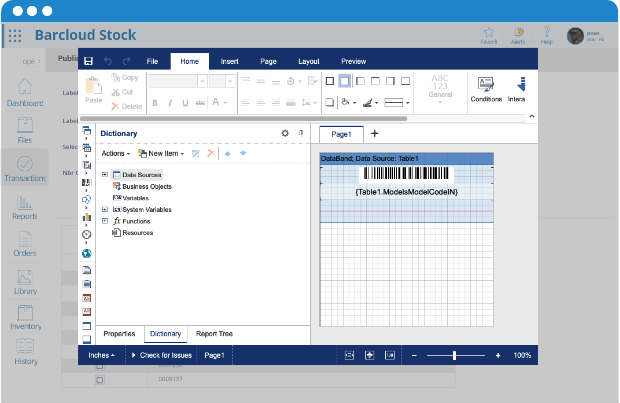

Bold Possibilities with our Barcode Software

Our Barcode Inventory system gives users the flexibility to manage and categorize their compounds in many ways. From serialized inventory to batched inventory we’ve got you covered. Once mastered, our system will help you streamline every step of the management process.

Our barcode scanning will also add mobility to your processes thanks to portable barcode scanners. Work from anywhere or even on the go with our software, providing you a way to reduce lead times and meet important deadlines.

The Benefits of of Our Barcode System

With our system, businesses will be able to enjoy a myriad of long-term benefits. Our Inventory System helps streamline order fulfillment and improve customer satisfaction. You will be able to establish safety stock levels to ensure you always have the correct amount of inventory available, can meet demand, and improve cash flow.

Our software also supports QR codes which can be attached to many surfaces including steel drums and other storage units. This helps facilitate efficient inventory tracking and identification of inventory items, further enhancing inventory management processes for companies utilizing our system.

Chemical Inventory Best Practices

Expiration Date Alerts

Chemical Inventory should have a specific expiration date which can be categorized and tracked as batched inventory. Our Inventory Management System triggers alerts when each batch/drum will reach its expiration date. This ensures all chemical barrels are used and no drum is overlooked.

Overstock Alerts

Hazardous materials should never be overstocked. Overstocking could lead to compound hazards. Our Inventory Tracking System alerts management if the substance rises above the predetermined level to prevent overstocking. This makes for effective inventory management.

Setting Default Locations

Some chemicals do not mix and become highly dangerous when stored together. Our Inventory System allows users to set default stocking locations to ensure compatible chemicals are put into a specified location. This ensures managed inventory is stored safely.

Reports

Having full visibility of what chemicals are available on site is very important. It ensures that every chemical is used completely before its expiration date. Our Inventory System provides a full reporting feature to keep accurate records of the chemical data. It will also conduct physical inventory counts and removes the need to physically count by hand.

Making the Transition

When using paper records, the possibility of error increases. Paper records might suffice for small-scale laboratories, but it will prove to be inefficient as you expand operations.

Managing large facilities with hundreds of chemicals requires a different managerial approach. Our Inventory System is the solution for any sized laboratories or warehouses. It can track chemicals from receipt to disposal, helping save time, resources, and provide accurate data.

Chemical Drum Inventory Tracking Features

Receive & Issue

Receive using PO’s and issue against SO’s

Multi-Site Compatibility

Separate your inventory between different warehouses or laboratories

Issue Out to Anyone

Issue inventory items to Customers, Job Sites, or Production Processes

Automatic Reorder Inventory Reminders

Set Up Automatic Reorder by Quantity

Inventory Counts

Conduct Physical Inventory and Cycle Count

Create & Configure Lists

Create Inventory Catalogs, Bill Of Materials (BOM), and Pick Lists

End to End Control and Accuracy

Our Inventory System provides knowledge of in-process usage and drum availability so you can focus on planning, production and shipments.

Our powerful inventory management system lets you create your own durable barcode labels. The particular data your teams need to see can also be configured within our barcode system. Data such as locations, batches, and serial or ID numbers associated with each drum.

FAQs

How do you track chemical inventory?

Chemical management can be streamlined in several ways, but the best way is using an inventory management system. Given the large amount of information that must be tracked, an automated barcode system can be used to assign each chemical inventory item a unique identifier that can be used to keep track of your chemical inventory.

Our Chemicals Inventory System is the perfect solution to your organization’s inventory tracking challenges, configurable to the needs of your chemical inventory.

Which is the best Chemicals Inventory Management Software?

When selecting the most suitable inventory management software for your facility’s chemical inventory, consider factors such as the scale of your operations, the specific requirements for tracking chemical inventory, scalability, integration capabilities, ease of use, and quality of customer support.

Speak to a representative for a demo of the best chemical inventory tracking system. Our system comes with features equipped to manage the expiration dates of your chemicals as well as keep track of the inventory levels of your consumable items.

How do you manage chemicals in a lab?

Common chemical inventory in labs includes sensitive chemicals, chemical drums and barrels, raw materials, pipettes, slides, and many more items! As such, using a good Chemicals inventory management system will help you effectively organize and track chemicals throughout their lifecycle.

Our chemicals inventory management software is adept at helping the lab keep track of chemical inventory at all stages, including procurement, storage, handling, use, cleanup, and disposal.

In The Work

Here are some new inventory features that we are currently working on. Stay tuned to see our inventory management software become even more powerful.

- Site Transfer

- Inventory Requisition For Internal Site Transfers

- Stock Cycle Count

- Customize Header Fields for Inventory Transactions

- Adding Authorization for Adjust & Dispose Transaction